Experts predict the warehouse racking market could be worth USD 11.40 billion by 2028, highlighting the importance of these vital pieces of equipment to a range of industries. In fact, many businesses would struggle to operate without these well-designed racking systems.

But, what are the different types of pallet racking and how can they help your business? After all, it’s essential to maximize your warehouse space to improve your workflows and increase profitability. The good news is there are many kinds of pallet racks that can match just about every warehouse storage need.

Let’s dive in and learn more about pallet racking systems.

Selective Pallet Racking

One of the most popular warehouse storage options is selective pallet racking as it offers superb picking ability. You can access pallets from either side of the equipment, allowing staff to find what they are looking for without any hassle. They can then move it to the next stage of the distribution process.

This racking style is what most people think of when they talk about pallet racks.

Push-Back Racking

A push-back rack allows a forklift operator to place pallets on nested carts that sit in lanes. Known as a first-in-last-out (FILO) system, the first cart moves to the back of the lane as others are added. When the forklift driver needs to remove a pallet, the last pallet that was placed in the lane will be the first one out.

This is a high-density storage system, ideal for holding large quantities of goods.

Pallet-Flow Racks

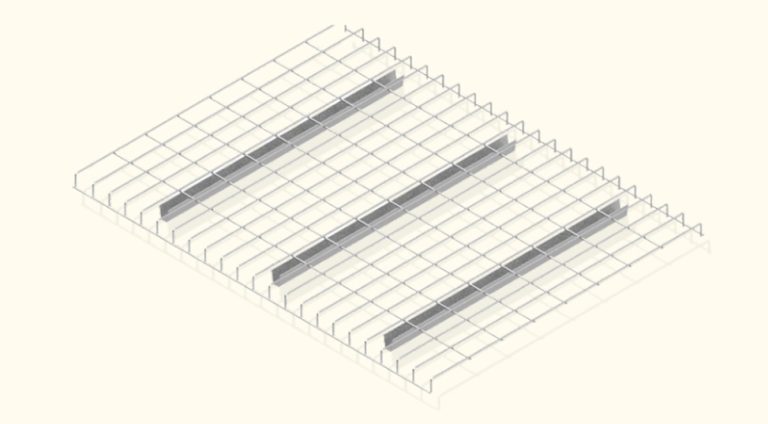

Pallet-flow racks are a first-in-first-out (FIFO) system. These allow forklift operators to load a pallet in at one end and take it off at the other. This can also be an excellent way to move heavy goods around the warehouse as you won’t be transporting items across a busy factory floor.

Installing pallet-flow racks can be useful when you are low on available space.

Drive-In Racking

When using drive-in racking, you can massively increase your inventory storage space. A forklift operator drives their vehicle into the racking system to easily add and retrieve goods.

However, you’ll want to ensure your equipment is well-protected from accidental damage. It’s a good idea to read more info about the different ways to look after your racking systems before making a purchase.

Cantilever Racks

These are probably the best pallet racks if you handle oversized goods such as steel poles or timber. Cantilever racks are strong and allow forklift drivers or crane operators to easily place goods on supporting arms that are attached to sturdy legs. These systems also offer adjustable height settings which can help with product spacing demands.

Take Your Time When Choosing Between Different Types of Pallet Racking

Knowing the different types of pallet racking means you can find the ones that are most suitable for your warehouse storage needs. While a particular rack design may be excellent for one requirement, you could also need a different type to store other goods. Therefore, to get optimal results across your entire warehouse floor, it may be best to combine a variety of pallet rack types.

But, by planning in advance, you can design a streamlined racking system layout that boosts your business’s productivity levels.

Before you rush out to buy pallet racking, be sure to check out more helpful posts in our Business section.