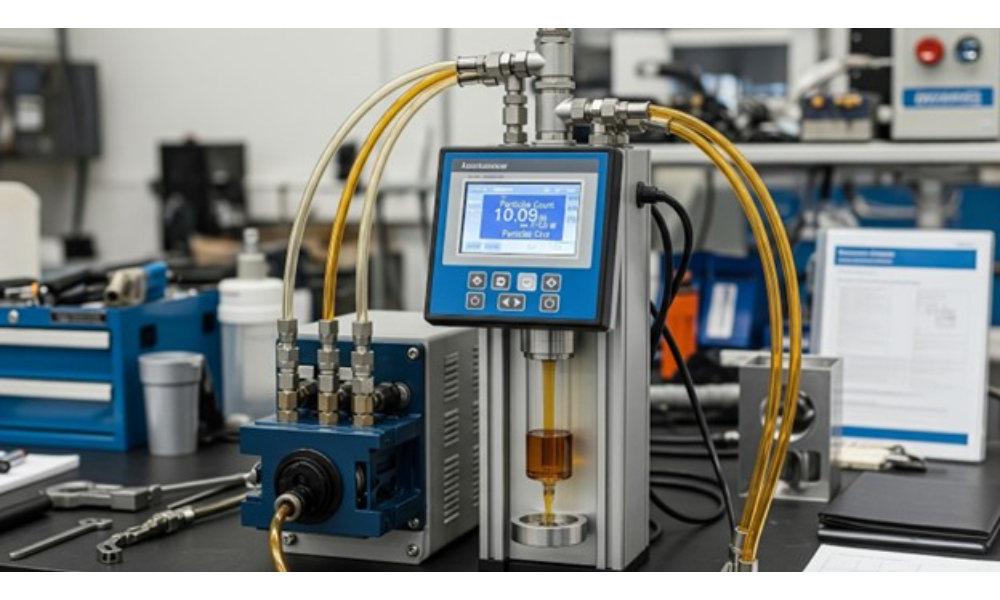

Clean hydraulic oil is essential to keeping your machinery efficient and dependable. When dirt, moisture, or microscopic debris enters your system, it can lead to wear and costly breakdowns. A hydraulic oil particle counter gives you real-time insight into contamination, helping you protect your equipment before damage occurs.

In this article, you’ll learn how this small yet powerful device enhances reliability, reduces costs, and transforms your maintenance strategy into one built on precision and performance.

1) Stop Wear Before It Starts

Tiny particles might seem harmless, but they can cause lasting harm. As contaminants move through hydraulic lines, they scrape against surfaces, reduce lubrication quality, and wear down seals. Over time, this affects performance and efficiency.

With effective hydraulic system contamination monitoring, you’ll spot contamination early and take preventive action. Early detection helps you maintain cleaner oil, protect internal components, and keep operations running smoothly.

2) Reduce Downtime and Maintain Consistency

Unplanned downtime interrupts schedules, halts production, and increases expenses. Contaminated oil is often the hidden cause behind it. When you monitor particle levels continuously, you can address issues before they grow into bigger problems.

Scheduled maintenance based on data, not guesswork, gives you more control. Instead of reacting to sudden failures, you’ll plan interventions when it’s convenient, improving uptime and operational flow.

3) Extend Equipment Lifespan

Your machines work best when they’re supported by clean, well-filtered oil. Even the smallest contaminants can accelerate wear and reduce overall lifespan. By integrating a hydraulic oil particle counter into your maintenance program, you’ll protect pumps, valves, and actuators from internal damage.

Monitoring oil quality regularly extends component life and maintains steady output. It’s a simple, data-driven way to protect your investment and avoid expensive replacements down the line.

4) Make Maintenance Smarter and More Efficient

Changing oil on a fixed schedule can lead to wasted resources. You might replace oil that’s still in good condition or overlook contamination that develops sooner than expected. Using advanced oil cleanliness testing equipment helps eliminate this uncertainty.

With accurate contamination data, you can make confident maintenance decisions. This targeted approach saves time, reduces material waste, and ensures that your hydraulic systems are always in top condition.

5) Improve Energy Efficiency and Performance

Contaminants make your system work harder. Dirt and particles increase resistance, forcing pumps to draw more power. Over time, this raises energy use and reduces performance.

By pairing a particle counter with fluid condition monitoring solutions, you’ll maintain oil at the right cleanliness level. Clean oil helps your equipment run smoothly, consume less energy, and deliver consistent power. The result is lower operating costs and greater efficiency.

6) Stay Confident with Compliance Standards

If you work in industries such as aerospace, manufacturing, or heavy machinery, clean oil isn’t optional, it’s a requirement. Maintaining fluid cleanliness ensures your systems meet international standards like ISO 4406 or NAS 1638.

A hydraulic oil particle counter simplifies this process by providing accurate ISO particle count analysis. You’ll have verifiable data for inspections, audits, and maintenance logs, showing your commitment to performance and quality assurance.

7) Save More by Preventing Future Repairs

Unexpected repairs are expensive, especially when equipment failure halts production. Investing in condition monitoring reduces the risk of breakdowns and unplanned expenses. When paired with a structured hydraulic maintenance and reliability plan, a hydraulic oil particle counter quickly proves its value.

Cleaner oil extends service intervals, reduces waste, and minimizes the need for emergency replacements. In the long term, these savings make contamination control one of the most cost-effective steps in modern maintenance.

Choose the Right Counter for Your System

Your equipment deserves a solution that fits its workload and design. Portable counters are excellent for spot checks, while inline systems continuously track cleanliness in real time. When selecting your model, consider flow rate, viscosity, and system pressure.

Choosing a counter that integrates easily into your process ensures consistent monitoring. With clear readings and reliable reporting, your maintenance team can make quick, confident decisions that keep the system stable.

Empower Your Team with the Right Knowledge

The best results come from trained people using the right tools. Teach your technicians how to interpret particle data and respond appropriately. When they understand contamination trends, they can adjust filters, schedule maintenance, or replace oil before it affects performance.

Consistent training also encourages accountability. When everyone works toward the same cleanliness standards, your operation becomes stronger, safer, and more efficient.

Build Predictability and Peace of Mind

Predictability brings confidence. With regular monitoring, contamination never goes unnoticed. Your system’s condition becomes measurable and manageable, which helps you plan maintenance with certainty.

Over time, your entire operation benefits from stability. Fewer disruptions, lower costs, and stronger performance all begin with one key action, keeping your oil clean and monitored.

Cleaner Oil, Stronger Performance

Clean oil is the foundation of reliability. A hydraulic oil particle counter helps you achieve it by detecting contamination early and providing accurate, actionable data. It keeps your systems efficient, your components protected, and your maintenance programs on track.

For information on hydraulic oil particle counters or assistance in choosing a suitable unit, contact SINTECH SCIENTIFIC (S.E.A.) PTE LTD today. Their team is available for inquiries, product details, and technical support.