It is a well-known fact that globalisation is tightening its grip on the world more and more. With the market situations changing from day to day, it is evident that the world’s industries have been busy operating at their highest operational capacities to cater to this ever-increasing demand for various supplies. Let it be pharmaceutical drugs or office stationeries, and factories have been clocking more production than ever, especially given the effects of the global pandemic and the subsequent lockdown-induced shortage of supplies all around the world. Companies worldwide are heavily scrutinised on their sites for a variety of environmental and ecological reasons as well. While specific industries that rely on a lot of chemicals and stuff for their operation are more prone to produce chemical waste, industries like mining and petrochemical refineries also contribute a lot to global pollution by emissions and effluents. Therefore, it has become a need of the hour to settle for a standardised approach to reduce wastage of resources due to improper planning or unscientific handling. Lean six sigma is an approach that has been making its name heard in industrial circles for quite some time now.

The ‘lean’ approach

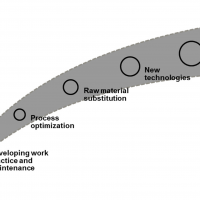

The word ‘lean’ in the lean six sigma approach has its roots well within the Japanese culture. According to this approach, the main focus is on steps that one must take to reduce waste and reduce the time spent supplying the products or services once the requests start coming in. This approach is also highly focused on making sure that customer satisfaction is also given the utmost care. Of course, one needs to know about a few other techniques and principles to implement the six-sigma system, too, like value-stream mapping, line balancing, and wastage reduction. This approach is a hugely popular step towards process optimisation, saving a ton of money, time, and other resources, which would themselves give way to more business and hence more profit.

Organic growth that fuels the company

One of the basic principles of the lean six sigma approach is to do a keen observation of the employees and to take even their opinions into the matter, making them feel important and thereby fuel them to work more heartfully for the company. A happy workforce would mean better care being taken on the produce, which would mean better quality of products, thereby increasing the longevity and quality. This would result in a happy customer base that would increase customer loyalty, putting the business at a much better place on the business charts and even better within their hearts.

The approach

One can safely say that nothing would work out without proper planning. However, given the sheer vastness of fields covered by various industries worldwide, it requires a thorough understanding of each of them to employ six sigma principles. They can be generalised as recognising, defining, analysing, improving, controlling, standardised, and integrating. The lean-six sigma approach specialises in this approach by bringing in certain other concepts mentioned earlier in this article. A tried and tested technique and the lean six sigma approach has been the values based on which modern companies like Toyota and General Motors set up their factories. Being certified in implementing these techniques across workplaces is a valuable skill that any business could use to take advantage of organic boosts in performance.