Diesel gas generators are a critical source of power in various industries, from manufacturing plants to data centers, and even in residential backup systems. With their reliability and fuel efficiency, diesel gas generators provide essential power support. However, like any mechanical system, they require regular maintenance and repair to ensure optimal performance and longevity. This article provides a comprehensive guide to diesel gas generator repair, outlining key steps and practices to maintain and repair these power units effectively.

Understanding the Importance of Diesel Gas Generator Maintenance

Regular maintenance is crucial to the efficient operation of diesel gas generators. Proper upkeep prevents unexpected breakdowns and extends the life of the generator. Maintenance tasks often include oil changes, coolant checks, fuel system inspections, and battery testing. Without proper attention, components like the engine, alternator, and electrical system may suffer damage over time, leading to costly repairs or replacements.

Key Benefits of Regular Maintenance:

- Extended Lifespan: Timely maintenance reduces wear and tear on components, allowing the generator to function for a longer period without major issues.

- Improved Efficiency: Well-maintained generators run more efficiently, using less fuel and providing more consistent power output.

- Reduced Downtime: Preventative maintenance minimizes unexpected failures, reducing operational downtime.

Common Diesel Gas Generator Repair Needs

Despite regular maintenance, diesel gas generators may encounter issues that require repair. Being aware of common problems can help ensure that timely and appropriate repairs are performed.

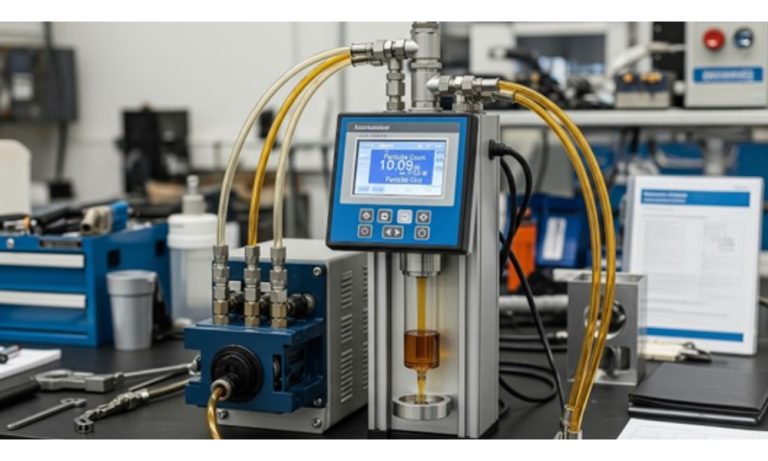

1. Fuel System Issues

One of the most frequent repair needs in diesel gas generators relates to the fuel system. Problems such as clogged fuel injectors, fuel contamination, or fuel leaks can affect the generator’s performance. These issues may lead to reduced efficiency or complete system failure if not addressed promptly.

Solution: Regularly inspect fuel lines and filters to prevent clogging and ensure clean fuel is supplied to the engine. If necessary, replace worn-out components such as fuel injectors or fuel filters.

2. Battery Failure

The battery plays a vital role in the starting mechanism of diesel generators. Battery failure can occur due to lack of charge, corrosion, or aging, leading to starting problems.

Solution: Routine battery inspections are essential. Check the voltage levels and clean terminals to prevent corrosion. Replace batteries that show signs of wear or diminished capacity.

3. Coolant Leaks and Overheating

Overheating is a serious issue that can damage the engine and other critical components. Coolant leaks are a common cause of overheating, often resulting from loose hoses, damaged gaskets, or worn seals.

Solution: Regularly monitor coolant levels and inspect the cooling system for leaks or damage. Replace worn hoses and seals, and ensure that the cooling system is functioning properly to prevent overheating.

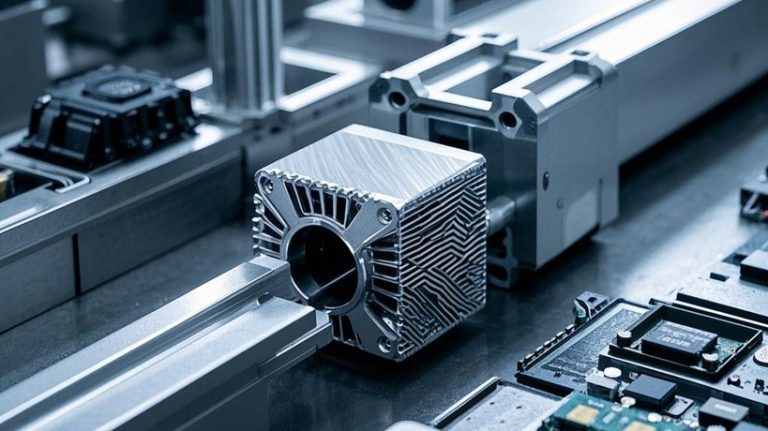

4. Electrical System Failures

Electrical system issues, such as faulty wiring, blown fuses, or malfunctioning control panels, can affect the generator’s ability to deliver power efficiently.

Solution: Regular electrical system inspections can help identify potential problems before they lead to major failures. Repairing or replacing faulty components, such as wiring or fuses, is crucial for maintaining optimal performance.

Steps in Diesel Gas Generator Repair

Proper diesel gas generator repair requires a systematic approach to diagnosing and fixing the issue. Below are the key steps involved in the repair process:

1. Initial Inspection and Diagnosis

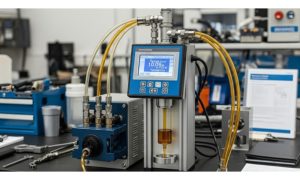

The first step in any repair process is a thorough inspection of the generator. Technicians should check for visible signs of wear, damage, or leaks. Diagnostic tools such as multimeters, pressure gauges, and engine analyzers can help pinpoint the exact problem.

2. Component Testing

Once the issue is identified, individual components may need to be tested. For example, if the problem lies within the fuel system, technicians will check the fuel lines, injectors, and filters. In the case of electrical failures, the alternator, control panel, and wiring will be tested for functionality.

3. Parts Replacement and Repair

After diagnosis and testing, damaged parts should be replaced or repaired. This may include replacing worn-out belts, cleaning clogged fuel injectors, or repairing coolant leaks. Using high-quality replacement parts is crucial to ensure the longevity and performance of the generator.

4. System Calibration and Testing

After repairs are made, it is important to calibrate the system and conduct performance testing. This ensures that the generator operates at optimal efficiency. Technicians should test the generator under load to verify that it can deliver power as expected.

5. Final Inspection and Documentation

After completing the repair and testing, a final inspection should be performed to ensure everything is functioning correctly. It is also essential to document the repairs made and any parts replaced for future reference.

Best Practices for Diesel Gas Generator Repair

To ensure the long-term reliability of a diesel gas generator, follow these best practices:

- Follow Manufacturer Guidelines: Always refer to the manufacturer’s guidelines for maintenance schedules and repair procedures.

- Use Qualified Technicians: Diesel gas generator repair should only be performed by trained and certified technicians who are familiar with the system’s intricacies.

- Maintain Detailed Records: Keep detailed records of maintenance and repairs. This helps track the generator’s condition and anticipate future repair needs.

- Perform Load Testing: Regularly test the generator under load to ensure it can handle the expected power demand during an outage.

Conclusion

Diesel gas generator repair is an essential aspect of maintaining power reliability and performance. By understanding common repair needs, following a systematic repair process, and adhering to best practices, you can ensure the longevity and efficiency of your generator. Regular maintenance, timely repairs, and professional expertise are key to preventing costly breakdowns and keeping your generator running smoothly for years to come.