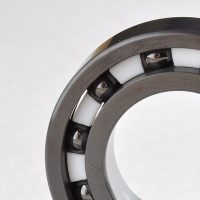

FTW Bearings get involved in many sectors, where they play vital roles in supporting machines and equipment. These components are considered necessary for reducing friction, supporting loads, and increasing the efficiency of mechanical systems.

In this blog, we will explore some of their many uses that showcase how they play a crucial role in several industries. So let’s get started!

What are the Uses of FTW Bearings?

Here are some critical uses of bearings across different sectors:

Automotive Industry

Bearings are extensively used in various vehicle components in the automotive industry. They are crucial to the smooth functioning of engines, transmissions, and wheel hubs. For instance, wheel bearings bear the weight of a car and let its wheels rotate with very little friction. Likewise, engine and transmission bearings ensure that the internal parts work smoothly, thus minimizing wear and tear and enhancing fuel efficiency.

Aerospace Industry

Bearings are vital in aerospace since they are the keys to maintaining reliability and precision. Aircraft engines, landing gear, and flight control systems are used. They should be capable of withstanding extremely high temperatures, fast speeds, and heavy loads while working perfectly.

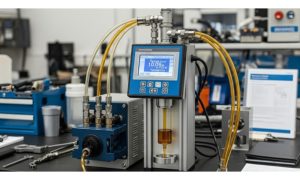

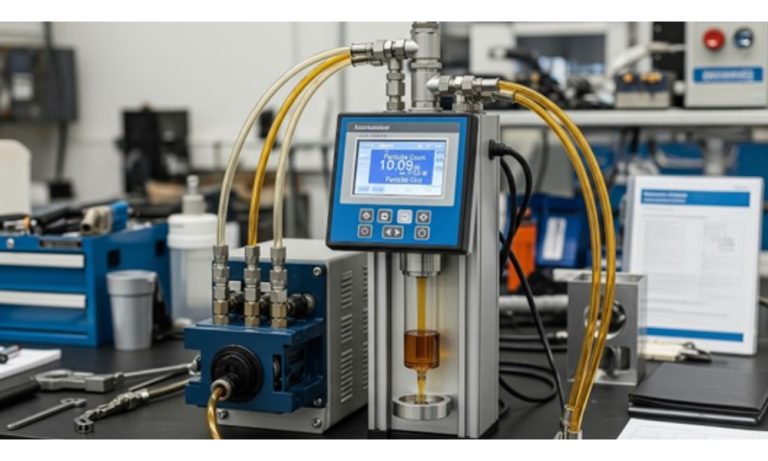

Industrial Machinery

FTW Bearings (ตลับลูกปืน FTW, which is the term in Thai) are one of the most frequently used types of bearings in industrial machinery since they can be found in various equipment such as conveyors, pumps, compressors, and electric motors. They help machines run smoothly and efficiently by minimizing friction between rotating components.

Consumer Electronics

Additionally, these bearings are present in consumer electronic equipment, contributing to their seamless function. Such devices as fan units, hard disks, and DVD players are used to lessen noise and vibration, yielding an improved user experience that is quieter and more efficient.

Construction And Heavy Equipment

In construction, these bearings are utilized in heavy machines like excavators, cranes, and bulldozers. These bearings must bear heavy loads and work in extreme conditions full of dirt, dust, and vibrations. These bearings provide the required efficiency and firmness that guarantee any industrial machine’s smooth and sound operation.

Conclusion

These bearings are adaptable and trustworthy elements employed by different sectors to increase the productivity and lifespan of machines or other devices. From vehicle usage and aircraft passing through production equipment to home appliances, bearings supply exactness, toughness, and the efficiency necessary for fluid movement. Their aptitude to endure difficult situations plus hold exquisite burdens establishes them as a pivotal option among specialists looking for superior-quality ball-bearing solutions.