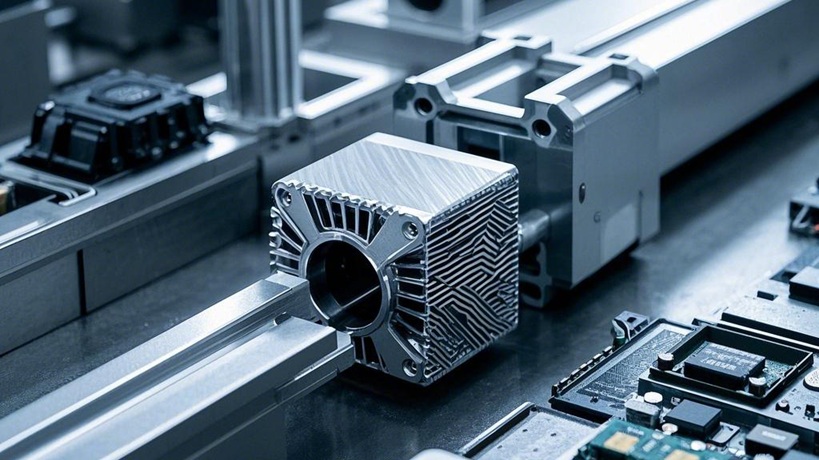

The Tungsten heat sink has emerged as a critical component in some of the most challenging thermal management scenarios facing modern engineering. In the remote control rooms of industrial facilities, the climate-controlled laboratories where advanced electronics take shape, and the harsh operational environments where failure carries severe consequences, tungsten quietly performs an essential task. This grey, dense metal, once primarily associated with light bulb filaments and industrial tooling, now stands at the forefront of thermal management technology, protecting sensitive electronics from the relentless threat of heat-induced failure.

The Problem of Extreme Heat

The story of thermal management in extreme environments is fundamentally a story about survival. Electronic components, regardless of their sophistication or cost, share a common vulnerability: they generate heat during operation, and excessive heat destroys them. In benign conditions, with moderate temperatures and adequate ventilation, conventional cooling solutions suffice. Aluminium heat sinks, copper spreaders, and standard air cooling handle most everyday applications without difficulty.

But extreme environments tell a different story. Consider the electronics aboard satellites, subjected to temperature swings from minus 150 to plus 120 degrees Celsius as they orbit between shadow and sunlight. Or the control systems in industrial furnaces, operating continuously in ambient temperatures exceeding 60 degrees Celsius. Think of the high-power laser systems used in manufacturing, where focused beams generate localized heat intensities that would vaporize ordinary materials. These applications demand more than conventional solutions can provide.

Why Tungsten Succeeds Where Others Fail

The Tungsten heat sink addresses extreme thermal challenges through a combination of physical properties that few materials can match. Tungsten melts at 3,422 degrees Celsius, a threshold so high that it renders thermal runaway scenarios virtually impossible in electronic cooling applications. This extreme temperature tolerance provides engineers with substantial safety margins, a crucial factor when designing systems for critical applications.

Beyond temperature tolerance, tungsten offers several distinct advantages:

- Thermal stability that maintains consistent performance across temperature extremes

- High density providing superior heat capacity per unit volume

- Low coefficient of thermal expansion minimizing stress on component interfaces

- Excellent mechanical strength at elevated temperatures where other metals soften

- Chemical inertness resisting degradation in corrosive or reactive atmospheres

Singapore’s Tungsten heat sink manufacturers have documented significant success in aerospace applications, where reliability cannot be compromised and operating conditions routinely exceed the capabilities of standard materials. The performance data from these implementations provides compelling evidence of tungsten’s advantages in extreme thermal environments.

Real-World Applications Under Pressure

In the defence sector, electronic systems must function reliably regardless of environmental conditions. Military radar installations in desert climates face ambient temperatures exceeding 50 degrees Celsius, whilst electronic warfare systems generate substantial internal heat loads. The Tungsten heat sink has proven invaluable in these applications, maintaining operational stability when mission success depends upon electronic reliability.

The oil and gas industry presents another demanding testing ground. Downhole drilling electronics operate in environments combining high temperatures, extreme pressures, and corrosive conditions. Standard cooling solutions fail rapidly under these combined stresses. Tungsten’s ability to withstand both thermal and chemical challenges has made it an increasingly common choice for critical components in subsurface instrumentation.

Power generation facilities, particularly those involving concentrated solar thermal systems or advanced nuclear designs, create environments where electronic controls must function reliably despite proximity to intense heat sources. The Tungsten heat sink provides the thermal management capability these systems require, protecting sensitive monitoring and control electronics that regulate complex processes.

Engineering Considerations and Trade-Offs

Selecting a Tungsten heat sink involves careful analysis of specific application requirements. Tungsten costs significantly more than aluminium or copper, the traditional heat sink materials. This cost difference means tungsten finds its niche not in everyday consumer electronics, but in specialized applications where its unique properties justify the investment.

Weight represents another consideration. Tungsten’s high density, whilst advantageous for thermal mass, creates challenges in weight-sensitive applications. Aerospace engineers must balance thermal performance against payload constraints, sometimes employing tungsten strategically in critical areas whilst using lighter materials elsewhere.

Manufacturing tungsten heat sinks requires specialized capabilities. The metal’s hardness and high melting point complicate traditional metalworking processes. Powder metallurgy techniques, whilst effective, add complexity and cost to production. Singapore’s Tungsten heat sink sector has developed considerable expertise in these manufacturing challenges, refining processes that yield reliable, high-performance components.

The Testing Ground

Proving thermal management solutions for extreme environments requires rigorous validation. Accelerated life testing subjects prototype heat sinks to temperature cycling, thermal shock, and sustained high-temperature operation. These tests reveal potential failure modes before systems deploy into service, where failures carry real consequences.

Thermal imaging and instrumentation provide detailed performance data, mapping temperature distributions and validating thermal models. The gap between predicted and actual performance, when it exists, drives design refinement. This iterative process, repeated across multiple design cycles, gradually optimizes heat sink geometry, interface materials, and integration approaches.

Looking Forward

As electronics continue penetrating harsh environments, from deep space exploration to geothermal energy systems, the demand for robust thermal management solutions will only intensify. The Tungsten heat sink stands ready to meet these challenges, its proven reliability and exceptional properties positioning it as an essential technology for applications where conventional approaches fall short. The engineers and technicians who specify, design, and deploy these systems understand a fundamental truth: in extreme environments, where heat threatens to destroy sensitive electronics and compromise critical systems, proven solutions matter more than cost savings, and reliability trumps convenience every time, making the Tungsten heat sink an indispensable ally in the ongoing effort to push electronic systems into ever more demanding operational territories.