Liquid filling machines play a pivotal role in various industries across Singapore, revolutionizing the way liquids are packaged and distributed. From pharmaceuticals to food and beverage, these machines have become indispensable for businesses seeking to enhance efficiency and accuracy in their production processes.

Types of Liquid Filling Machines Available in Singapore

In Singapore, businesses have access to a wide range of liquid filling machines to suit their specific needs. Manual liquid filling machines provide a cost-effective solution for smaller-scale operations, allowing operators to control the filling process manually. Semi-automatic machines offer a balance between manual control and automation, ideal for medium-sized enterprises looking to streamline their production lines. For large-scale operations requiring maximum efficiency, fully automatic liquid filling machines are the preferred choice, capable of filling hundreds of bottles or containers per minute with precision and speed.

Benefits of Using Liquid Filling Machines in Singapore

The adoption of liquid filling machines in Singapore brings a plethora of benefits to businesses. Increased efficiency and productivity are perhaps the most significant advantages, as these machines can fill containers rapidly and accurately, minimizing downtime and maximizing output. Precision in filling operations ensures consistency in product quality, reducing wastage and errors that could impact profitability. Moreover, by complying with industry standards and regulations, businesses can uphold their reputation for safety and quality while avoiding costly penalties.

Factors to Consider When Choosing Liquid Filling Machines in Singapore

When selecting a liquid filling machine in Singapore, several factors must be taken into account to ensure optimal performance and suitability for the intended application. The type of liquid being filled and its viscosity will dictate the type of filling mechanism required, whether it be gravity, piston, or vacuum filling. Production capacity and speed requirements must also be considered to match the machine’s capabilities with the demands of the business. Space constraints, budgetary considerations, and the availability of after-sales support and maintenance services are additional factors that can influence the decision-making process.

Best Practices for Maximising the Performance of Liquid Filling Machines in Singapore

To maximize the performance and longevity of liquid filling machines in Singapore, businesses should adhere to best practices aimed at ensuring efficiency and reliability. Regular maintenance and calibration are essential to keep the machines operating at peak performance, minimizing the risk of breakdowns and downtime. Operator training and implementation of safety measures are crucial for preventing accidents and injuries in the workplace. Integration with other packaging machinery, such as capping and labelling systems, can further streamline the production process and improve overall efficiency. Additionally, implementing monitoring and quality control processes enables businesses to identify and rectify any issues promptly, ensuring consistent product quality and customer satisfaction.

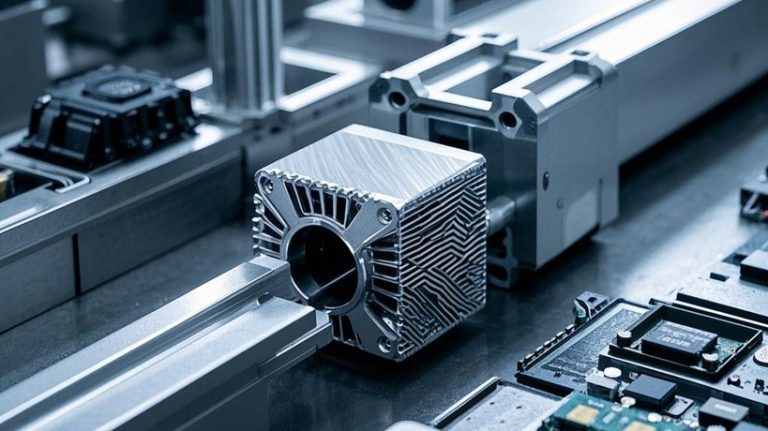

Leading Suppliers and Manufacturers of Liquid Filling Machines in Singapore

Singapore boasts a vibrant marketplace for liquid filling machines, with several reputable suppliers and manufacturers catering to the diverse needs of businesses across various industries. These suppliers offer a comprehensive range of liquid filling equipment, including automated systems, customised solutions, and innovative technologies designed to enhance efficiency and productivity. Customer reviews and satisfaction ratings provide valuable insights into the performance and reliability of different machines, helping businesses make informed decisions when selecting a supplier.

Future Trends and Innovations in Liquid Filling Machines

As technology continues to advance, the future of liquid filling machines in Singapore looks promising, with a focus on automation, robotics integration, and sustainable practices. Automated systems equipped with artificial intelligence and machine learning capabilities are poised to revolutionize the industry, enabling greater precision, flexibility, and efficiency in filling operations. Advancements in filling technologies, such as non-contact filling methods and inline quality control systems, will further enhance product quality and reliability. Additionally, the adoption of sustainable practices, such as eco-friendly materials and energy-efficient designs, reflects a growing awareness of environmental concerns and a commitment to sustainability in the manufacturing sector.

Liquid filling machines play a vital role in enhancing efficiency, accuracy, and productivity in various industries across Singapore. By choosing the right machine and implementing best practices, businesses can unlock new levels of efficiency and competitiveness, positioning themselves for success in an ever-evolving marketplace.