Automation in the manufacturing sector began on a brutal note way back in the 1970s. It got a further boost with the arrival of robotic arms in the late 1990s. But the speed at which digital technologies, particularly Artificial Intelligence (AI), have evolved over the past two decades, has opened up various possibilities, including the more widespread use of robots in different industrial sectors, including manufacturing.

How can JDE help implement robots in manufacturing?

JD Edwards or JDE is a leading software solution provider for large-scale operations spanning many industries, including manufacturing and supply chain.

It offers complete and industry-leading solutions for the deployment and management of robots in different industrial sectors, including manufacturing. It has over 6000 large and medium-sized businesses as its clients, many of which are Fortune 500 companies.

How are robots changing the work environment in manufacturing?

Local Factories Boom: Robots are not always giant and gigantic. They can be tiny as well. And they can also be just any size between the smallest and biggest sizes. This means that soon robots could be available for any task — small or big. One of the fallouts of this development can be the mushrooming of small factories. Many people are now finding self-employment with automated or semi-automated machines. These small factories may produce parts for larger vendors.

Productivity and Competitiveness: The use of robots in manufacturing has helped improve production at low-cost inputs. With increased production and productivity, the competitiveness of the products also becomes higher. This means the use of robots can cut costs, increase production, and keep the MRP low. This is a great advantage for all manufacturers.

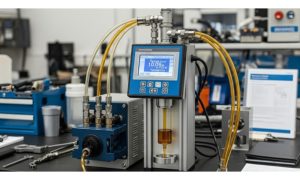

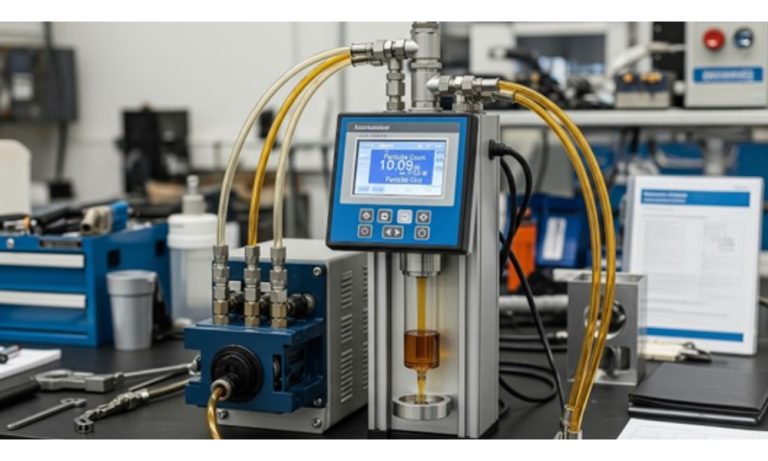

Safety to workers: Some jobs involve hazardous activities. Human workers often become victims of accidents in their workplace. Robots can substitute humans in those functions. Typical use cases can be the use of remote-controlled robots to deal with hazardous chemicals, environments, and equipment. Robots are now being used for repetitive and heavy lifting jobs.

A new industrial revolution is around the corner

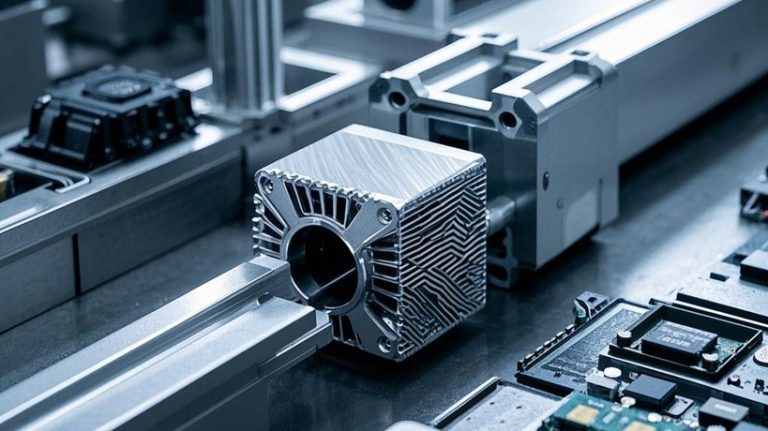

By now, robotic hands’ videos performing both easy and challenging tasks with complete precision at vehicle manufacturing plants have become quite widespread.

These videos highlight how robots, or robotic hands, as they are more popularly referred to, can perform repetitive tasks with complete precision without experiencing the fatigue that human workers experience. Similar robotic hands are replacing human workers across different manufacturing sectors.

This has led the manufacturing industry to feel that it’s on the verge of a new industrial revolution. It’s going to boost production at unbelievable proportions and speed. Electric car maker Tesla hopes that it will increase its vehicle’s production to 1 million per year shortly. There is no comparison available at the moment to this scale of manufacturing ambitions. Indeed, an industrial revolution of sorts is round the corner.

Robots are going to become much more intelligent

Large manufacturing companies such as automakers are looking at a future where robots would bring a range of benefits. These include cost-cutting, large and quick production, and enhanced safety to human workers. These are not the ultimate goals of having robots in the manufacturing sector. This is just the beginning. These are the use cases of robots with limited AI. At the moment, they are only mimicking the human work process.

New developments in robotics aim at machine learning, and there are already significant developments in this direction. Machine learning is the process where the machine or the robot begins to self-learn and respond to changing situations based on the data it generates and from those from other sources.

Robots use AI, a combination of software, smart devices, and deep learning, which is nothing but vast amounts of data, and the system’s ability to quickly analyze it. So, in the next 10 to 20 years, robots will become more commonplace. They will show manufacturing capability that the world has not seen so far. Even imagining that scenario fully right now is not possible.

Final Thoughts

Modern robots use limited AI to perform repetitive and heavy-duty tasks. They have already changed the dynamics of many production plants across different industrial sectors. They can make the production process smooth, productive, and fast.

They can make the entire manufacturing more cost-effective. What’s more? The future for them looks more promising with new developments making them all the more intelligent and efficient. No wonder they are revolutionizing the manufacturing sector.