In the world of manufacturing and material processing, success often hinges on the smallest thing. Among them are grinding media that are small but whose importance in ultimate performance and lifespan is by no means minor. If you work with wet or dry milling, fine grinding, or precise polishing, having the proper grinding media is essential to delivering consistent results and minimizing downtime.

From industrial grinding media to specialty tumbling media and even processes affecting catalyst bed preparation, Fox Industries knows that performance starts in the middle. And that middle stands on material science, application knowledge, and reliability. In this article, we shall observe how using the right grinding media can boost output, reduce costs, and extend the life of both your products as well as equipment.

Understanding the Role of Industrial Milling Media

Industrial milling media is used in numerous industries like mining, ceramics, chemical, and pharmaceutical. It is the motive force for decreasing particle size, dispersion, and homogenization. The right media can speed milling to be more rapid, efficient, and cost-effective.

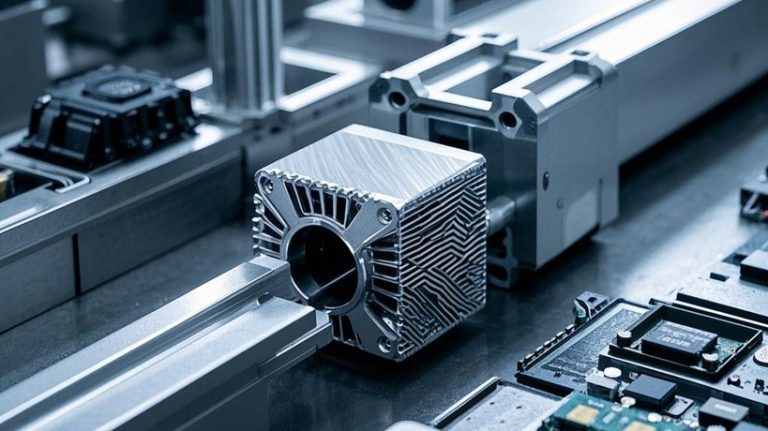

Industrial milling media design is what makes it unique. Each is tailored to the type of milling environment, either high-speed horizontal mills or low-impact vertical systems. The media utilized affects milling time, energy, heat production, and ultimately product quality.

Too much wear, contamination, and wasted power result from a media-application mismatch. Precise selection is the reason why. It isn’t just about picking grinding media — it’s about picking performing media.

Factors That Regulate Fine Grinding Media

It is not machine-one-size-fits-all when choosing grinding media. There are certain key factors that must be considered when it comes to making the right choice for the best outcome:

Material Type: Stainless steel to ceramic, each having their own set of parameters such as hardness, density, and chemical resistance.

Shape and size: Geometry controls the material flow within the mill, interaction among other particles, and distance of pressure transmission.

Strength: The media should withstand extended milling time without breaking, deteriorating, or losing their effectiveness.

Risk of contamination: Some processes require very clean products, and some grinding media are sufficiently clean on their own to provide such cleanliness.

Stainless steel tumbling media has been the preferred option for virtually all high-performance milling operations since it is corrosion-resistant, reusable, and hard.

The Power of Stainless Steel Tumbling Media

Of numerous different grinding and tumbling media, stainless steel is one of the best for where power and purity are both needed. Stainless steel tumbling media is especially found to function exceptionally well in tough grinding applications where plenty of impact is needed.

Why do so many industries employ stainless steel?

Strength: Stainless steel media remains strong with enhanced strength, lasting longer than ceramic or glass media alternatives.

Consistency: All the applications ensure consistent results, which is necessary in high-volume or regulation applications.

Low contamination: Stainless steel doesn’t shed particulates that can contaminate products, as compared to other materials.

Stainless steel tumbling media is the optimum selection for grinding, polishing, and finishing operations where cleanliness and precision are an absolute necessity.

How Tumbling Media Determines Surface Quality

Tumbling media is at the heart of post-processing, especially in those sectors where the surface finish is cosmetic to greater than cosmetic. Deburring metal parts, edge-rounding sharp edges, and polishing parts to a mirror-finish – tumbling media guarantees consistency with less manual work.

Proper tumbling media can save processing time, cut waste, and enhance final product quality. Stainless steel tumbling media, in particular, can allow high-tolerance polishing and finishing without flattening or degradation under load. It is usually the default choice in aerospace, auto, and medical manufacturing where quality is simply not negotiable.

Associating Milling Media with Catalyst Bed Efficiency

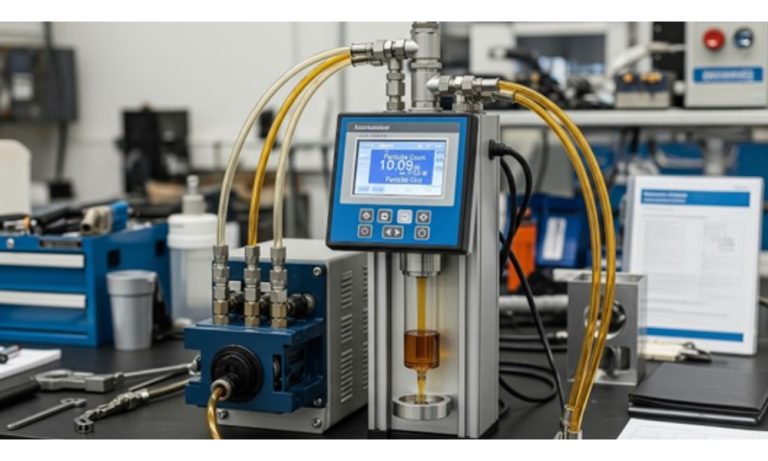

It may not be immediately obvious, but grinding media has a direct effect on catalyst bed performance in gas processing, oil-refining, and petrochemical industries. Materials have to be milled to precise particle shapes and sizes prior to being loaded into a catalyst bed. The efficiency of chemical reaction would most often depend on the structure and the homogeneity of the bed itself.

Accurate industrial grinding media ensures particles to be ground in a consistent manner, increasing the way tightly and uniformly they pack in a bed of a catalyst. This makes for level liquid or gas flow, reduces pressure buildup, and extends the life of the bed. Improved grinding media results in improved reaction conditions

The Fox Industries Difference

At Fox Industries, we don’t merely sell grinding media — we engineer performance. Our products are designed to meet the demands of the most stringent industrial processes. We offer a broad range of industrial milling media, tumbling media, and stainless steel solutions that give our customers confidence and consistency.

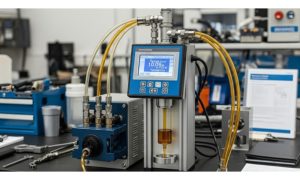

Our grinding media are rigorously tested for performance, wear, and degree of contamination so you can get the most out of your investment. From ultra-fine milling to aggressive polishing to preparation of catalysts, we will help you find the right match for your application.

Final Thoughts on Making the Right Choice

Grinding media is tiny but its influence is gigantic. The choice of the correct one affects everything from power consumption to product quality and processing time. Your operation can experience improved performance and wear resistance in the long term with stainless steel tumbling media and custom-designed industrial milling solutions from Fox Industries.

The right media not only makes your system work, it makes it better.