Removable jet fire PFP systems are gaining industry traction due to their ability to provide high-performance fire protection while allowing for inspection, maintenance, and reinstallation without significant downtime. However, their adoption depends heavily on rigorous testing protocols that validate performance under extreme conditions. Testing procedures must meet international fire safety standards while reflecting the unique properties of removable PFP materials compared to traditional fixed coatings.

Understanding the Purpose of Testing

Testing protocols for removable jet fire PFP are designed to simulate real-world fire exposure, specifically the high-temperature, high-pressure conditions caused by jet fires from pressurised hydrocarbon releases. These fires can reach temperatures of up to 1,200°C and exert significant mechanical force on structures. Testing ensures that removable systems can maintain their insulating properties, prevent structural failure, and limit temperature rise on protected steel during a designated fire exposure period. The goal is to prove not only compliance with safety standards but also performance parity with, or superiority over, fixed PFP solutions.

International Standards and Guidelines

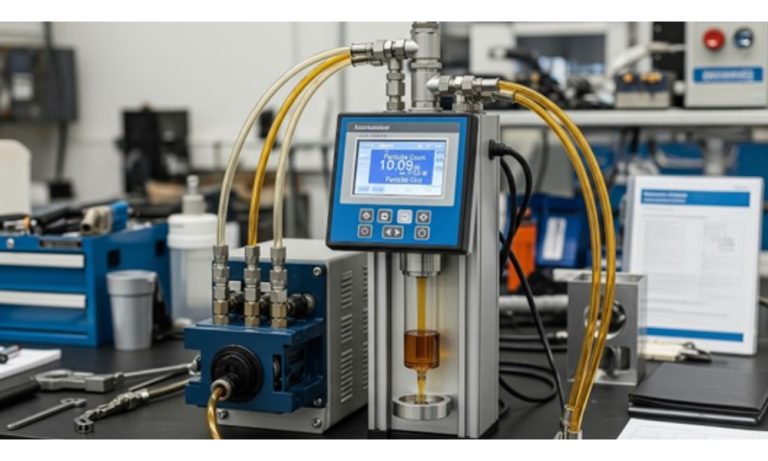

The primary testing benchmarks for removable jet fire PFP come from recognised standards such as ISO 22899-1 for jet fire testing and additional oil and gas sector specifications like those from the HSE, Shell, or API. ISO 22899-1 requires that the PFP system be exposed to a jet fire under controlled laboratory conditions, measuring backside steel temperature and system integrity over a defined period. Removable systems must also demonstrate that the reinstallation process after removal does not compromise fire resistance, meaning repeated testing cycles may be needed to validate ongoing performance after maintenance events.

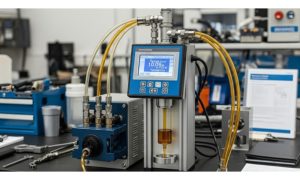

Thermal and Structural Performance Tests

Thermal testing focuses on temperature rise limits for structural steel, typically aiming to prevent it from exceeding 400–620°C, depending on the design standard. Removable PFP materials are subjected to direct jet flame exposure with thermocouples placed at critical points to measure heat transfer. Structural performance tests evaluate how well the system stays in place under the high-velocity impact of jet fires. Since removable systems may have fastening points, panels, or wraps instead of bonded coatings, testing must confirm that these attachment mechanisms remain secure under prolonged fire and vibration exposure.

Reusability and Maintenance Verification

Unlike permanent coatings, removable jet fire PFP systems must be tested for their reusability. This testing involves removing and reinstalling the protection multiple times, then re-testing for fire resistance. The aim is to confirm that repeated handling does not degrade the material’s insulating properties or mechanical stability. Such tests are particularly relevant for offshore platforms and petrochemical facilities where regular inspection of the underlying steel or process equipment is required. This instance is a critical differentiator from conventional PFP testing, as long-term performance depends on the system’s resilience to both fire and operational wear.

Environmental Resistance Testing

Jet fire performance alone is insufficient without proving that the removable PFP can withstand environmental challenges such as salt spray, humidity, UV exposure, and chemical contact. Accelerated ageing tests simulate years of environmental exposure, after which the material is subjected again to jet fire testing. This instance ensures that removable systems remain effective even after extended deployment in harsh offshore or onshore environments. Corrosion resistance of the fastening hardware is also tested for systems used in marine oil and gas applications to ensure longevity.

Certification and Quality Control

Once the testing process confirms performance, the removable jet fire PFP system can be certified by the relevant authorities. Certification is not a one-time event; it requires ongoing quality control during manufacturing and periodic re-certification. It often includes batch testing to confirm material consistency and audits of fastening system designs to ensure uniformity across installations. Many operators also adopt their own in-house acceptance criteria, supplementing standard tests with operational trials before full-scale deployment.

Conclusion

The reliability of removable jet fire PFP systems depends on stringent, multi-stage testing protocols that go beyond standard jet fire assessments. These protocols ensure that removable systems deliver dependable fire protection without compromising operational flexibility by evaluating thermal resistance, structural integrity, reusability, and environmental durability. These testing standards will remain central to the adoption of removable PFP technologies as the oil, gas, and petrochemical industries prioritise both safety and maintainability.

Visit Ancloz to discuss tailored fire protection solutions for your specific operational environment.