Proper maintenance of your line striping equipment ensures that it operates efficiently and extends its lifespan. Whether you’re using a field line marking machine for athletic fields or other striping tools, giving attention to routine upkeep can save you time, money, and frustration. Follow these five essential tips to keep your equipment in top condition.

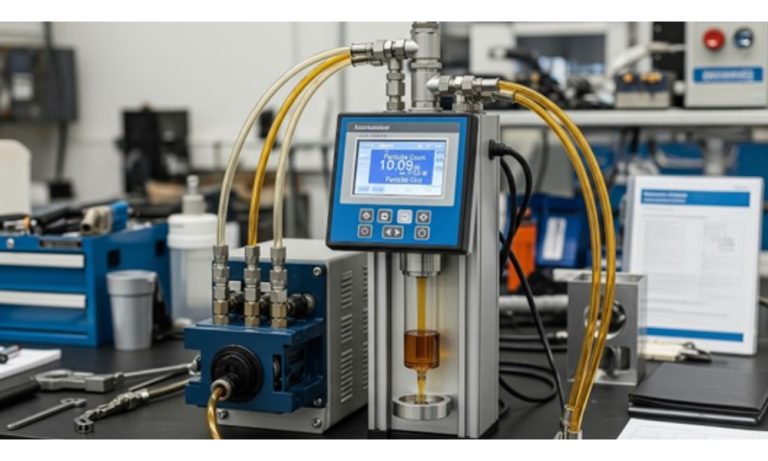

Clean Equipment After Every Use

After each use, take the time to clean your line striping equipment thoroughly. Paint buildup can clog nozzles, reducing the quality of your lines and potentially damaging the machine. Remove any excess paint from spray tips, hoses, and other critical components. Using mild solvents or water, depending on the type of paint used, can help maintain proper functioning and avoid long-term issues.

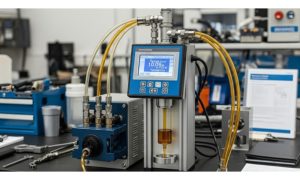

Inspect and Replace Worn Parts

Frequent inspection of your equipment is vital for spotting signs of wear and tear. Check components like nozzles, hoses, and wheels for any visible damage or deterioration. Worn parts can impact the precision of your line markings and may lead to costly repairs if ignored. Replace damaged or outdated parts promptly to ensure smooth operation.

Store Your Equipment Properly

Storing your equipment in a clean, dry area protects it from environmental damage, such as rust or moisture buildup. If possible, keep it covered to prevent dust and debris from settling on critical parts. Proper storage not only maximizes its lifespan but also ensures it’s ready for use when needed.

Perform Regular Lubrication

Lubrication is crucial for any machinery with moving parts, and line striping equipment is no exception. Regularly lubricate components like bearings, gears, and other mechanical parts to reduce friction and wear. Using the appropriate lubricant recommended by the manufacturer will help maintain smooth operation and decrease the risk of breakdowns.

Follow Manufacturer Maintenance Guidelines

Lastly, always refer to the maintenance manual for your equipment for specific care instructions. Each machine has unique requirements for cleaning, adjustments, and part replacement. Adhering to these guidelines will ensure that you’re maintaining your equipment correctly and avoid unintentional damage caused by improper handling.

By implementing these basic maintenance tips, you’ll keep your line striping equipment working efficiently while ensuring consistent, high-quality results.

Conclusion

Proper maintenance of line striping equipment is crucial for maintaining its performance and extending its lifespan. By regularly cleaning, inspecting, lubricating, and following manufacturer guidelines, you can prevent breakdowns and ensure smooth operation. This will also result in professional-looking lines that are essential for a successful striping job. Don’t neglect the maintenance of your equipment – it will save you time, money, and headaches in the long run.

FAQs

- How often should I clean my line striping equipment?

It is recommended that you clean your equipment after each use or at least once a week if you use it frequently. This will prevent the buildup of debris and paint residue, which can affect the performance of the machine.

- Can I use any type of lubricant on my equipment?

No, it is important to follow the manufacturer’s guidelines for lubrication. Using the wrong type of lubricant can cause damage to your equipment.

- What are some signs that my line striping equipment needs maintenance?

If you notice uneven lines, clogging or spitting from the spray nozzle, unusual noises, or difficulty starting or operating the machine, it may be time for maintenance.